Flashover in Small Enclosures: Unmasking the Rapid Threat and Advanced Protection Strategies

July 28, 2025 | Orbis Fire

Flashover in Small Enclosures: Unmasking the Rapid Threat and Advanced Protection Strategies

Executive Summary

Flashover, the sudden and near-simultaneous ignition of all combustible surfaces within an enclosed space, represents a critical and often underestimated fire hazard. In small enclosures such as electrical cabinets, server racks, and control panels, this phenomenon escalates with alarming speed, frequently within seconds to under a minute, far outpacing the response capabilities of traditional room-level fire suppression systems. This report delves into the unique fire dynamics of these confined spaces, highlighting how heat reflection, limited ventilation, and high fuel loads accelerate flashover. It critiques the inherent limitations of conventional fire detection and suppression for internal enclosure fires and advocates for advanced, localized micro suppression technologies. By understanding the science and implementing targeted protection strategies, organizations can safeguard critical assets, prevent catastrophic operational downtime, and mitigate significant financial and safety risks.

1. Introduction: The Unseen Fire Hazard in Critical Enclosures

Beyond Conventional Fire Risks: Why Small Spaces Demand Attention

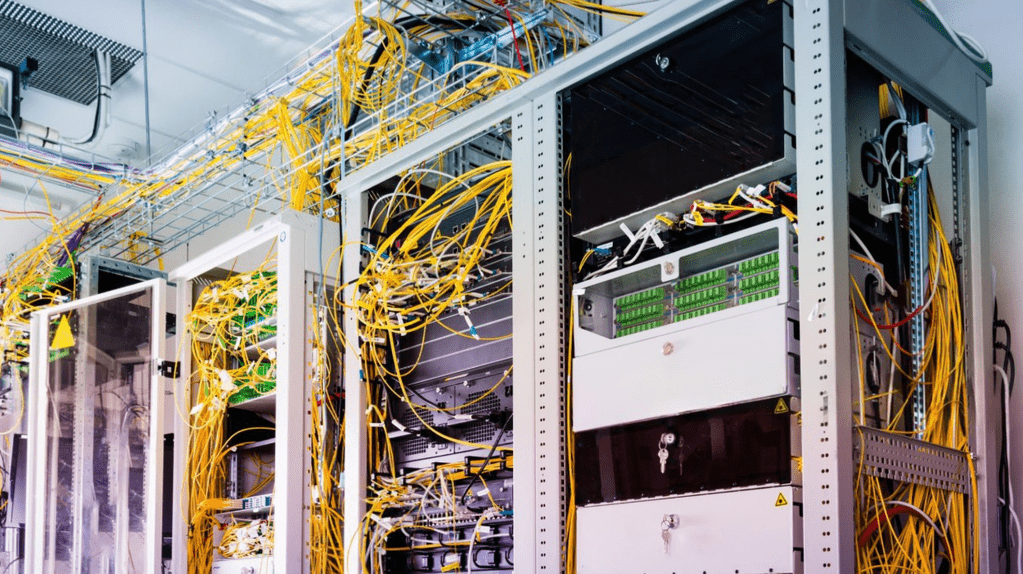

While large room fires often capture public attention, some of the most intense and destructive fires originate within the seemingly innocuous confines of small electrical cabinets, machine panels, server racks, and control enclosures. These compact spaces, often overlooked in broader fire safety plans, pose a unique and rapidly escalating threat. The very design of these enclosures, which prioritizes component density and protection from external elements, inadvertently creates ideal conditions for rapid fire development.

The scale of this vulnerability is significant. According to the National Fire Protection Association (NFPA), fires originating in electrical distribution equipment, including panels and cabinets, account for over 13,000 incidents and more than $600 million in property damage in the US annually. The high frequency and substantial property damage figures underscore that these are not isolated incidents but a systemic vulnerability across various industries, demanding specialized, proactive protection beyond general building fire safety measures. Many of these incidents are severe precisely because their rapid escalation occurs before external detection or intervention is possible.

Defining Flashover: A Catastrophic Tipping Point in Fire Dynamics

Flashover is a critical stage in fire development where all combustible surfaces within an enclosed space are heated to their ignition temperature and ignite almost simultaneously, leading to full room involvement or total involvement of the compartment. This transition marks a rapid and dramatic increase in heat release rate and temperature within the confined space.

Scientifically, flashover occurs when the temperature inside a space rapidly climbs past 500°C (932°F). At this critical point, the radiant heat becomes so intense that every exposed surface begins to release flammable gases through a process known as pyrolysis, and even materials not yet actively burning can ignite all at once. The radiant heat flux on unignited materials typically reaches a threshold of 15-20 kW/m². This phenomenon, characterized by its suddenness and overwhelming intensity, transforms a localized fire into a fully developed inferno in a matter of moments.

2. The Accelerated Science of Flashover in Confined Spaces

The confined nature of small enclosures fundamentally alters fire dynamics, creating conditions that drastically accelerate flashover compared to open environments. Understanding these mechanisms is crucial for effective prevention and suppression.

2.1. Fundamental Fire Dynamics: Pyrolysis, Radiant Heat, and Fuel-Air Mixtures

Fire growth is fundamentally driven by a complex feedback loop involving pyrolysis, radiant heat transfer, and the dynamics of the fuel-air mixture. Pyrolysis is the thermal decomposition of solid materials under heat, which liberates flammable gases. These gases then mix with the available air, forming a combustible mixture that can ignite and sustain a flame.

As the initial fire grows, it generates heat that is continuously radiated back to the unburnt fuel surfaces and the internal surfaces of the enclosure. This process, known as “thermal radiation feedback,” is a relentless and cumulative cycle. In a confined space, the proximity of all surfaces intensifies this feedback, rapidly driving up ambient temperatures and exponentially increasing the burning rate. Research indicates that once flashover conditions are reached, burning rates can become greater than double the free-burn rate observed in open conditions. This amplified thermal feedback is a primary scientific mechanism explaining the rapid acceleration of flashover in any enclosure, and its effect is particularly pronounced in small, sealed spaces where heat cannot easily escape.

The concept of a “stoichiometric ratio” describes the ideal mixture of oxygen and a fuel gas or vapor that, upon combustion, releases the maximum energy in the shortest period, leaving no residual oxygen or fuel. In the volatile environment of a confined space fire, the dynamics of this mixture are highly unpredictable, contributing to the rapid and intense nature of flashover.

2.2. The “Oven Effect”: Heat Reflection and Rapid Temperature Buildup

Small, enclosed spaces inherently function as miniature ovens during a fire. Heat generated by the initial ignition cannot easily dissipate into the surrounding environment. Instead, it becomes trapped, and the internal surfaces of the enclosure, particularly reflective metal or plastic components, bounce radiant energy directly back into the core of the fire. This continuous reflection and recirculation of thermal energy rapidly increases the internal temperature of the enclosure.

The physical dimensions of the enclosure are a primary determinant of its ability to dissipate heat. A larger surface area allows for more efficient heat transfer to the outside, resulting in a lower internal temperature rise. Conversely, smaller enclosures, by their very nature, concentrate heat far more effectively, accelerating the temperature climb towards flashover. The material composition of the enclosure also influences this effect; unfinished aluminum and stainless steel enclosures, for instance, can exhibit higher internal temperature rises compared to painted metallic or non-metallic enclosures due to their less efficient radiant heat transfer properties. The inherent design of electrical enclosures, which often prioritizes component density and protection from external elements, inadvertently creates ideal conditions for this “oven effect,” effectively transforming them into miniature, high-risk fire traps.

2.3. The Critical Role of Limited Ventilation and Pressure Dynamics

Limited ventilation is a pivotal factor in the rapid escalation of enclosure fires. In sealed or semi-sealed enclosures, the hot gases and smoke produced by a fire cannot escape efficiently, leading to a swift increase in internal temperature and pressure. As the heat intensifies, the air and combustion gases within the enclosure expand, causing a rapid buildup of internal pressure. This pressure can exert significant stress on enclosure seals, potentially leading to cracks, leaks, or even a catastrophic physical failure of the enclosure itself.

A dangerous paradox emerges in highly confined spaces: if oxygen becomes depleted due to rapid combustion, the fire can become “ventilation-controlled”. While this might temporarily reduce visible flame intensity, it simultaneously fosters the accumulation of large amounts of unburnt, superheated flammable gases (pyrolysis products) within the enclosure. This hidden hazard creates an extremely volatile environment. The sudden introduction of fresh air into such an oxygen-starved, fuel-rich atmosphere—for example, if the enclosure is opened or a seal fails—can result in a violent “backdraft” or “smoke gas explosion”. In such an event, the accumulated gases ignite explosively, causing rapid burning and potentially expelling flames and burning materials beyond the enclosure. This underscores the extreme danger associated with delayed intervention or improper ventilation in these environments. Regulatory bodies, including OSHA, recognize the severe hazards posed by flammable gas and dust accumulation in unventilated enclosures and mandate specific ventilation and explosion relief measures to mitigate these risks.

2.4. High Fuel Load: Combustible Materials in Electrical and IT Enclosures

Electrical cabinets, server racks, and control panels are inherently densely packed with a diverse array of combustible materials. This high fuel load contributes significantly to the rapid escalation of fire once ignition occurs.

Wiring and Cable Insulation: The cabling within these enclosures often utilizes various polymeric insulation materials, each with distinct fire properties:

Polyvinyl Chloride (PVC): While PVC has a relatively lower melting point (around 80°C/176°F) compared to some other plastics, it possesses inherent fire resistance due to its high chlorine content. It typically will not continue to burn once the heat source is removed and frequently achieves favorable UL 94 V-0 ratings for wire and cable applications. However, the combustion of PVC can release hydrogen chloride (HCl) gas, which is a highly irritating and potentially deadly byproduct.

Acrylonitrile Butadiene Styrene (ABS): ABS can withstand higher temperatures (with a melting point around 105°C/221°F) and can be formulated with flame retardants to achieve UL94 V0, V1, or V2 ratings, making it suitable for electrical housings.

Polyethylene (PE): A common cable insulation material, polyethylene inherently exhibits poor fire resistance and is flammable. Its fire properties can be improved through the addition of fillers or by cross-linking it to produce XLPE (cross-linked polyethylene).

Rubber Insulation: Used in some cables, rubber insulation produces dense, black, oily smoke and releases toxic gases such as hydrogen sulfide (H2S) and sulfur dioxide (SO2) when burned.

Circuit Boards and Electronic Components: Printed Circuit Boards (PCBs) are central to electronic equipment, and their flammability is evaluated against standards like UL 94V-0, which signifies high flame retardancy and self-extinguishing capabilities. Despite these ratings, PCBs can still ignite due to overheating from excessive current flow, inadequate cooling, or poor soldering. Once a PCB ignites, the intense heat can cause components to melt, release toxic fumes, and even lead to explosive events. Specific components like hard drives, motors, and batteries are recognized as primary sources of smoke or fire due to their propensity to overheat.

Dust and Oil Residue: Accumulated dust and debris within electrical enclosures are critical fire hazards. Combustible dust can interfere with the normal operation of electrical components, leading to overheating or short circuits. Furthermore, dust acts as an insulating layer, trapping heat and accelerating component wear. Critically, when dust is suspended in the air within a confined space, it can lead to highly destructive “flash fires” or “dust explosions”. A primary explosion can dislodge additional dust, leading to a more destructive secondary explosion. Oil residue, often found in machinery panels, also serves as a readily ignitable fuel source.

The combination of these diverse materials, some with inherent flame retardancy and others highly flammable, creates complex and unpredictable fire behavior within enclosures. Moreover, the presence of toxic flame retardants in recycled plastics, frequently used in electronics , introduces the potential for unexpected and hazardous chemical releases during a fire.

Table 1: Key Fire Properties of Common Electrical Enclosure Materials

Material Type | Flammability/Ignitability (Key Metrics) | Heat Release Rate (Peak HRR, kW/m²) | Smoke Production (Key Metrics) | Key Toxic Byproducts (Examples) |

PVC Insulation | UL 94 V-0 (common), LOI > 30 (less likely to burn in air) | Low (e.g., 17.5 – 56.8) | High optical density (e.g., 470-535 Dm) | Hydrogen Chloride (HCl) (deadly, irritating) |

ABS Plastic | UL 94 V0, V1, V2 (formulated), LOI 17.6 | High (e.g., 70.7 – 1311) | High optical density (e.g., 780 Dm) | Ketones, Aldehydes (from electrical fires) |

Polyethylene (PE) Insulation | Poor fire resistance, flammable , LOI 17.0 | Very High (e.g., 88 – 2735) | High optical density (e.g., 150-470 Dm) | Carbon Monoxide (CO), Carbon Dioxide (CO2), Aldehydes |

Rubber Insulation | Oxygen Index > 27 (can be fire resistant) | Not specified | Dense, black, oily smoke | Hydrogen Sulfide (H2S), Sulfur Dioxide (SO2) |

Circuit Boards (PCBs) | UL 94V-0 (high flame retardancy, self-extinguish) | Varies widely | Varies widely | Toxic fumes (general), PCBs (from electrical burning) |

Combustible Dust | Flash fire/explosion hazard when suspended | Varies widely | Significant smoke from explosion | Particulates, CO, CO2, other combustion products |

Oil Residue | Supports combustion if thick enough (>1-2mm) | Varies widely | Gases and particulates (soot) | SO2, NO2, CO, PAHs |

Note: Data from various sources and test conditions. Values are illustrative and can vary based on specific formulations and test methodologies.

This table highlights the inherent flammability and potential for toxic byproduct release from materials commonly found within electrical enclosures. It visually reinforces the “high fuel load” and “toxic byproduct” aspects of enclosure fires, allowing for a quick understanding of the inherent risks.

3. The Devastating Consequences of Enclosure Flashover

Flashover in small enclosures, while initially contained, can rapidly lead to widespread damage and severe repercussions for businesses and facilities. The speed and intensity of these events leave minimal time for intervention, amplifying their destructive impact.

3.1. Operational Paralysis: Data Loss and Extensive Downtime

Fires in critical electrical and IT enclosures can lead to immediate and severe operational disruptions. The intense heat generated by a flashover, often reaching 500°C (932°F) , can cause catastrophic hardware failure, leading to irreversible data corruption and rendering stored information inaccessible. The rapid onset of flashover, which can occur in mere seconds to under a minute , means that by the time a fire is noticed outside an enclosure, significant data loss and operational paralysis may have already occurred.

The financial implications of such downtime are staggering. Reported costs for businesses average around $9,000 per minute. This rapid escalation of a fire event directly translates into immediate and substantial economic losses, as the minimal time for intervention means that the maximum financial impact is incurred almost instantaneously. For small businesses, the consequences can be existential, with 50% of those experiencing data loss due to hardware failures going out of business within two years. This amplifies the urgent need for instantaneous internal suppression to preserve operational continuity and mitigate financial devastation.

3.2. Financial Burden: Equipment Replacement and Recovery Costs

Beyond immediate operational losses, flashover events necessitate extensive and costly equipment repair and replacement. The extreme temperatures, which can reach up to 35,000°F from an arc flash, a common ignition source in electrical enclosures , are capable of melting and vaporizing metal components. The accompanying pressure waves generated by such events can physically damage equipment and lead to structural failures within the enclosure itself.

The financial burden extends far beyond the cost of the directly affected equipment. Even seemingly minor electrical fires, such as those in a bedroom, can incur costs ranging from $1,625 to $26,715, while attic electrical failures can reach $4,115 to $46,225. These figures escalate dramatically for complex industrial machinery, server racks, or data center equipment, where specialized components and installation labor add significant expense.

Furthermore, smoke and soot, often overlooked as destructive agents, cause significant and insidious damage to sensitive electronics. A black film from smoke can coat both the interior and exterior surfaces of electronic components, creating an insulating effect that leads to overheating and premature system failure. The magnetic charge within smoke can also cause electrical shorts in delicate circuitry. If not addressed quickly, soot can permeate electronics, leading to permanent corrosion and further functional degradation. This multi-layered destruction from heat, pressure, and corrosive smoke creates complex, expensive, and prolonged recovery efforts, extending the impact far beyond the initial burn.

3.3. The Invisible Threat: Toxic Byproducts of Electrical Fires

The combustion of materials commonly found in electrical enclosures, particularly plastics, wiring insulation, and electronic components, releases a hazardous cocktail of toxic gases and particulate matter. This “invisible threat” poses severe and immediate health risks to personnel, extending the impact beyond property damage to human safety and long-term health.

Key asphyxiants produced include carbon monoxide (CO) and hydrogen cyanide (HCN). These gases interfere with the body’s ability to utilize oxygen, leading to central nervous system depression, unconsciousness, and ultimately death due to tissue hypoxia.

Irritant gases, which cause severe respiratory issues and can hinder escape, are also prevalent. These include hydrogen chloride (HCl) from the combustion of PVC , as well as hydrogen fluoride (HF), sulfur dioxide (SO2), and nitrogen dioxide (NO2). Phosgene, a highly toxic gas, can also be produced through the hydrolysis of HCl and CO.

Other dangerous byproducts from burning plastics and electronic components include ketones, aldehydes, benzene, naphthalene, polycyclic aromatic hydrocarbons (PAHs), dioxins, dibenzofurans, isocyanates, and perfluoroisobutylene (PFIB). Some of these, such as polychlorinated biphenyl (PCB) by-products, are linked to cancer and other serious long-term health issues. The presence of toxic flame retardants in recycled plastics, often incorporated into electronic devices , further adds to the concern regarding unexpected chemical releases during a fire. The diverse and highly toxic nature of these combustion byproducts from electrical equipment fires underscores the critical life-safety aspect of rapid suppression, as limiting exposure is paramount.

4. Why Traditional Fire Suppression Systems Fail in Small Enclosures

Conventional fire suppression systems, designed primarily for open room environments, are fundamentally inadequate for addressing fires that originate and rapidly escalate within small, enclosed electrical and IT cabinets. Their design and activation mechanisms are mismatched to the unique dynamics of enclosure fires.

4.1. Delayed Detection: The Inadequacy of Room-Level Sensors

Traditional room-level smoke and heat detectors are inherently too slow to effectively detect and respond to fires originating inside sealed or semi-sealed enclosures. The physical structure of the enclosure acts as a significant barrier, severely restricting the flow of smoke and heat. This containment prolongs the time it takes for fire indicators to escape the cabinet and reach a ceiling-mounted detector, delaying crucial alarm activation.

Compounding this issue, many electrical and IT enclosures are equipped with internal cooling fans or air conditioning systems. While essential for maintaining optimal operating temperatures for the equipment, these systems inadvertently dilute and cool any smoke produced by an internal fire. This dilution and cooling effect reduces the smoke’s thermal buoyancy, preventing it from rising effectively to the ceiling where traditional detectors are typically installed, further prolonging response time.

Furthermore, conventional fire alarm panels typically detect by “zone” rather than pinpointing a specific location. This can significantly delay emergency responders from identifying the exact source of the fire. By the time a room-level detector activates and an alarm is raised, the fire inside the enclosure has likely already reached or surpassed flashover, rendering external intervention largely ineffective for preserving the equipment itself. This critical time gap between internal flashover and external detection highlights the fundamental inadequacy of traditional detection methods for protecting sensitive enclosure contents.

4.2. Ineffectiveness of Overhead Sprinklers and Total Flooding Gas Systems

Even if a room-level detection system eventually triggers, the subsequent activation of traditional suppression systems presents significant limitations for internal enclosure fires.

Overhead Sprinklers: Room-based sprinkler systems are designed to react to large, open-air fires. They typically activate when the ambient room temperature reaches a specific threshold, such as 68°C (155°F) for standard sprinklers, or up to 141°C (286°F) for high-temperature applications. However, flashover within a small enclosure occurs at much higher temperatures, typically around 500°C (932°F). This significant temperature mismatch means that by the time sufficient heat from an internal flashover escapes the enclosure and raises the room temperature to activate a sprinkler, the critical equipment inside is already irreversibly damaged by the intense heat and flame.

While fire codes generally permit sprinklers in electrical rooms , their activation can cause substantial collateral damage to sensitive electronics through water exposure. This can lead to equipment failure, extensive data loss, or even trigger additional electrical hazards like arc flash events. The damage inflicted by water often outweighs any benefit of suppression for the internal equipment, emphasizing a fundamental mismatch between the solution and the specific problem of internal enclosure fires.

Total Flooding Gas Suppression Systems: These systems aim to fill an entire room or large compartment with a fire suppression agent, such as CO2 or various clean agents, to reduce oxygen concentration or absorb heat, thereby extinguishing the fire. A major limitation of total flooding systems is their reliance on a high degree of enclosure integrity to retain the extinguishing agent for a specified “hold time,” typically 10 to 20 minutes, which is crucial for effective fire suppression and preventing re-ignition. Small electrical enclosures, with their numerous cable penetrations, seams, and access points, are rarely airtight enough to meet these stringent hold time requirements, leading to rapid agent leakage and compromised effectiveness.

Furthermore, if an enclosure is too tightly sealed, the rapid discharge of a gaseous agent can cause significant pressure changes that may exceed the structural strength of the enclosure, leading to physical damage. To mitigate this, pressure relief vents are often required, but these add complexity, cost, and can introduce additional points of failure. Another critical consideration is life safety: some agents, like CO2, are toxic to humans and can displace oxygen to fatal levels. Their use is therefore limited to unoccupied areas, posing a significant risk if deployed in regularly accessed spaces. This further highlights the practical limitations and fundamental mismatch of total flooding systems for protecting individual, often accessible, electrical enclosures.

Table 2: Comparison of Traditional vs. Localized Suppression System Effectiveness for Enclosure Fires

Feature | Traditional Room Sprinklers | Traditional Total Flooding Gas Systems | Localized Micro Suppression Systems |

Detection Mechanism | Room-level heat/smoke detectors | Room-level smoke/heat detectors | Heat-sensitive detection tubes, direct flame/heat detection |

Activation Time | Delayed (reacts to room temp, after enclosure flashover) | Delayed (reacts to room temp, requires hold time) | Instantaneous (ruptures at ignition point) |

Target Area | Entire room/compartment | Entire room/compartment | Inside the enclosure, at the source of fire |

Collateral Damage | Significant water damage to electronics/equipment | Potential pressure damage to enclosure ; Agent toxicity risk (CO2) | Minimal (clean agent, targeted discharge) |

Suitability for Sensitive Electronics | Poor (water damage, potential arc flash) | Moderate (no residue, but hold time/pressure issues) | Excellent (non-conductive, no residue, precise) |

Power Requirement | Typically requires building power | Typically requires building power | Often operates without external power |

Cost Implications for Equipment | High (replacement, extensive cleanup, downtime) | High (replacement, complex installation, downtime) | Low (containment, minimal downtime, targeted repair) |

Compliance Standards | NFPA 13, NFPA 75 (room level) | NFPA 2001, NFPA 75 (room level) | Aligns with HBSE principles (IEC 62368-1), UL recognized |

This table visually summarizes the key differences and advantages of localized micro suppression systems over traditional room-level approaches. It clearly illustrates why specialized protection is not merely an option but a necessity for safeguarding critical electrical and IT enclosures.

5. The Strategic Advantage of Localized Micro Suppression Systems

To effectively combat flashover in small enclosures, fire suppression must occur directly at the ignition point, inside the enclosure, before the fire can escalate. Localized micro suppression systems are specifically designed to meet this critical requirement, offering a strategic advantage over conventional methods.

5.1. Precision Protection: Stopping Fires at the Ignition Point

Localized micro suppression systems represent a paradigm shift in fire protection for critical enclosures. Unlike room-level systems that react to a fire once it has grown large enough to affect the ambient environment, these systems are engineered to detect and extinguish fires precisely where they start, within the confines of the electrical cabinet or server rack. This precision protection is paramount because it limits fire damage to the immediate area of origin, preventing the fire from becoming a widespread catastrophe that compromises entire facilities. By containing the incident to the cabinet, organizations can significantly reduce downtime and ensure business continuity.

5.2. Advanced Mechanism: Heat-Sensitive Detection Tubes and Targeted Nozzles

Localized micro suppression systems leverage advanced technology for rapid and accurate fire response. They often employ heat-sensitive detection tubes that are flexible enough to be routed through the tightest and most complex spaces within an electrical panel or enclosure, placing the detection element directly adjacent to potential ignition sources.

These systems typically operate in one of two ways:

Direct Release Systems: In this configuration, the detection tube itself serves as both the detection device and the discharge mechanism. When high heat or actual flames are detected, the portion of the tube nearest the hottest point ruptures. This rupture creates a precise spray nozzle, through which the extinguishing agent is immediately released from the cylinder, directly onto the fire. This direct application ensures that the agent is delivered exactly where it is needed, at the earliest possible moment.

Indirect Release Systems: For larger or more complex cabinets, the detection tube in an indirect system triggers a separate valve when a fire is detected. This valve then discharges the suppression agent through dedicated nozzles strategically placed throughout the enclosure, allowing for broader and more comprehensive coverage of the protected volume.

A significant advantage of many micro suppression systems is their inherent independence from external power sources. They operate pneumatically, ensuring that they remain fully functional and ready to activate even if an electrical fault disables the main power supply to the equipment or facility. This power independence is a critical feature, as electrical faults are often the root cause of these fires. The design of these localized systems directly addresses the unique challenges of enclosure fires by providing rapid, precise, and resilient intervention.

5.3. Clean Agents for Sensitive Electronics

The choice of extinguishing agent is crucial for protecting sensitive electrical and IT equipment. Localized micro suppression systems typically utilize “clean agents,” which are gaseous or liquid agents that effectively extinguish fires without leaving behind any residue, unlike water or dry chemical powders. This characteristic is vital for electronics, as traditional water-based systems can cause extensive damage, corrosion, and data loss.

Clean agents, such as Halocarbon agents (e.g., FM-200, Novec 1230, Fluoro-K) or Inert gas agents (e.g., Inergen, Argonite), extinguish fires primarily by absorbing heat or by reducing the oxygen concentration to a level insufficient for combustion, while remaining safe for human respiration in occupied spaces (with the exception of CO2, which is typically reserved for unoccupied areas due to its toxicity). Their non-conductive properties ensure that they will not short-circuit live electrical components, further protecting sensitive circuitry. By minimizing collateral damage and eliminating the need for extensive cleanup, clean agents significantly reduce downtime and recovery costs, allowing for a faster return to normal operations. This ability to suppress fires without harming the very assets they protect is a cornerstone of effective localized fire suppression for modern electrical and IT infrastructures.

6. Proactive Measures: Beyond Suppression for Comprehensive Safety

While localized micro suppression systems offer an unparalleled advantage in rapidly containing enclosure fires, a truly comprehensive fire safety strategy integrates these advanced suppression technologies with proactive design principles and rigorous preventative maintenance.

6.1. Hazard-Based Safety Engineering (HBSE) in Equipment Design

Modern safety standards, such as IEC 62368-1, have shifted towards a Hazard-Based Safety Engineering (HBSE) approach for audio/video, information, and communication technology equipment. This philosophy mandates that fire safety is not an afterthought but an integral part of product design from conception. HBSE focuses on identifying potential energy sources within equipment (including thermal energy that can lead to ignition) and implementing safeguards to mitigate associated risks under normal, abnormal, and single-fault conditions.

This translates into concrete design requirements for internal components and enclosures. Manufacturers are expected to limit material temperatures to 90% or less of their spontaneous ignition point and utilize materials with specific flammability ratings (e.g., UL 94 V-0 or V-1) for combustible parts, especially near potential ignition sources. For certain high-power circuits or secondary lithium batteries, a dedicated “fire enclosure” may be required to prevent fire spread from within the component to the outside of the equipment. The evolution of standards like NFPA 75, which now permits performance-based designs and addresses complex issues like aisle containment in data centers, also reflects this move towards more flexible and targeted solutions that consider inherent safety. This emphasis on designing safety into the product from the ground up complements localized suppression systems, as it reduces the likelihood of ignition and contains initial hazards, making suppression even more effective.

6.2. Preventative Maintenance and Thermal Management

Rigorous preventative maintenance (PM) and effective thermal management are crucial first lines of defense against enclosure fires, directly addressing root causes and significantly mitigating flashover risk even before ignition. An Electrical Preventive Maintenance (EPM) program is critical for detecting issues before they escalate into expensive failures, reducing fire risks and unplanned downtime.

Key elements of a robust EPM program include:

Visual Inspections: Regular checks for signs of overheating, discoloration, corrosion, physical damage, and contamination in panels, switchgear, wiring, and insulation.

Thermographic (Infrared) Scans: These scans identify invisible hot spots that may indicate overloaded circuits, loose connections, or imbalanced loads, which are common precursors to electrical fires.

Insulation Resistance Testing: Measures the condition of insulation to detect breakdown before arcing or short-circuiting occurs.

Cleaning: Accumulated dust and grime act as insulation, trapping heat and accelerating wear, thereby increasing fire risk. Regular cleaning of components and removal of dust and debris (using non-conductive methods and approved vacuums to prevent dust explosions) are essential for maintaining thermal performance and preventing ignition. Dust is a multi-faceted hazard, acting as fuel, an insulator, and a source for secondary explosions.

Effective thermal management is paramount for the stable operation and longevity of electronic components. Research indicates that the reliability of electronic components can be cut in half for every 18°F (10°C) rise above normal room temperature. Proper enclosure design incorporates both passive cooling (e.g., strategically placed vents for natural convection) and active cooling solutions (e.g., fans or dedicated air conditioners) to dissipate heat generated by internal components. Circulating fans within an enclosure can significantly improve heat dissipation and eliminate hot spots by mixing internal air. Neglecting proper ventilation can lead to overheating, moisture buildup, pressure issues, and ultimately, expensive damage and safety hazards. By implementing these proactive measures, organizations not only reduce the likelihood of fire but also extend the operational lifespan of critical equipment.

7. Conclusions and Recommendations

Fires in small electrical and IT enclosures present a unique and exceptionally dangerous challenge. The inherent fire dynamics within these confined spaces—driven by the “oven effect” of heat reflection, the rapid accumulation of superheated gases due to limited ventilation, and the high concentration of diverse combustible materials—accelerate fire growth to flashover in a matter of seconds to minutes. This rapid escalation fundamentally outpaces the response capabilities of traditional room-level fire detection and suppression systems, which are designed for larger, open spaces and react too slowly to prevent catastrophic damage to sensitive internal equipment. The consequences are severe, ranging from immediate operational paralysis and staggering financial losses due to downtime and equipment replacement, to the release of highly toxic byproducts that pose significant health risks.

To effectively mitigate this rapid threat, a strategic shift in fire protection is imperative.

Recommendations:

Prioritize Localized Micro Suppression Systems: Organizations should invest in and implement localized micro suppression systems directly within critical electrical cabinets, server racks, and control panels. These systems offer unparalleled precision, detecting and extinguishing fires at the ignition point in seconds, before flashover can occur and before collateral damage spreads. Their independence from external power and use of clean agents are critical advantages for protecting sensitive electronics.

Integrate Hazard-Based Safety Engineering (HBSE): Manufacturers and system integrators should fully embrace and apply Hazard-Based Safety Engineering (HBSE) principles (e.g., IEC 62368-1) in the design and selection of equipment. This involves building inherent fire safety into components and enclosures through careful material selection, thermal management, and internal fire containment measures, thereby reducing the likelihood of ignition and limiting initial fire growth.

Implement Robust Electrical Preventive Maintenance (EPM): Establish and rigorously adhere to comprehensive EPM programs that include regular visual inspections, thermographic scanning, thorough cleaning (especially for dust and debris), and insulation testing. These proactive measures address the root causes of electrical fires, prevent overheating, and reduce the overall fuel load, significantly lowering the risk of flashover.

Recognize the “Time Gap” Imperative: Acknowledge that typical fire department response times and conventional room-level suppression activation are insufficient to prevent flashover and its devastating consequences within small enclosures. This understanding should drive the adoption of immediate, internal suppression solutions as the primary defense for critical equipment.

Conduct Comprehensive Risk Assessments: Regular and detailed risk assessments specifically for electrical and IT enclosures should be performed. These assessments must consider the unique fire dynamics, fuel loads, ventilation characteristics, and potential consequences of flashover within each specific enclosure, guiding the selection and placement of appropriate localized protection.

By adopting a multi-layered approach that combines advanced localized suppression with proactive design principles and rigorous preventative maintenance, organizations can effectively protect their critical assets, ensure operational continuity, and safeguard personnel from the rapid and destructive force of flashover in small enclosures.

We specialize in the production of automatic fire suppression systems designed to ensure the safety of various assets and industries. Our commitment to protection is at the core of our solutions, providing a reliable guarantee for safeguarding your assets.

Recent News and Blogs

Modular Data Center Fire Suppression: Protecting Racks with FIRESCI DLP and ILP Clean Agent Systems

Modular data centers are quickly becoming the go-to solution for organizations that demand reliable, scalable, and efficient IT infrastructure. These prefabricated or modular server rooms pack servers, battery storage, networking, and power equipment into high-density racks and enclosures. With valuable data and mission-critical systems at stake, a single fire incident can lead to devastating downtime, equipment loss, and business interruption. That’s why choosing the right fire suppression system for modular data centers is crucial.

The Real Cost of Skipping Fire Protection in Electrical Cabinets

Small electrical cabinets are integral to modern infrastructure, housing critical components that ensure the smooth operation of various systems. However, neglecting fire protection in these compact enclosures can lead to catastrophic consequences. This article delves into the tangible and intangible costs associated with inadequate fire protection in small electrical cabinets, providing installers and developers with a comprehensive understanding of the stakes involved.

How Fire Starts: A Breakdown of the Fire Triangle in Real-World Industrial Settings

Fires in industrial environments pose significant threats, leading to substantial property damage, operational disruptions, and, most tragically, injuries and fatalities.

A comprehensive understanding of how fires initiate and the implementation of robust prevention and suppression strategies are therefore paramount for ensuring safety and business continuity.