CO₂ Fire Suppression Systems

CO₂ Fire Suppression Systems – DHP / IHP Series

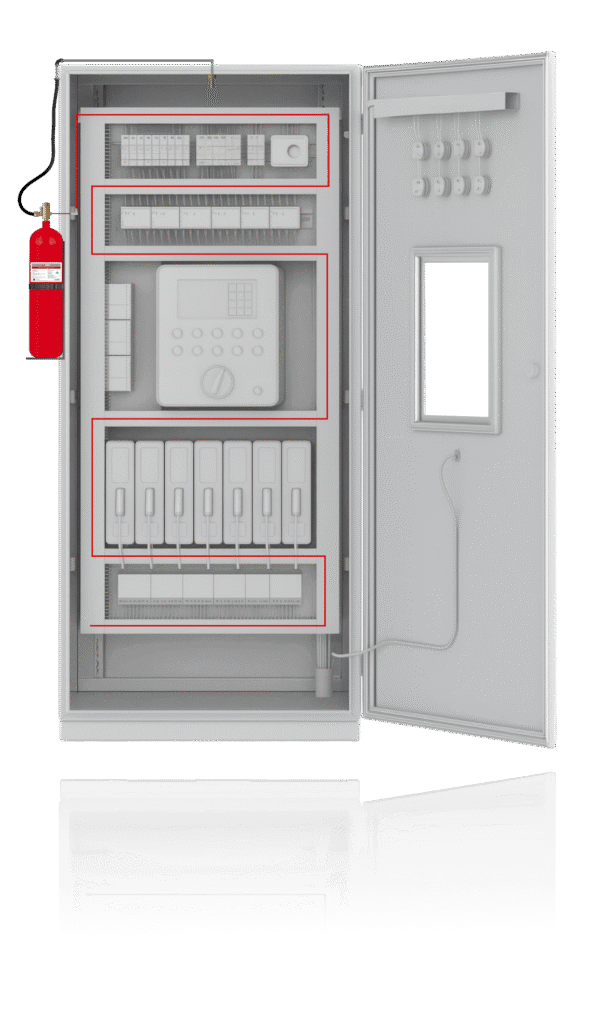

The Orbis® DHP and IHP CO₂ Fire Suppression Systems are engineered to deliver fast, effective fire protection for electrical enclosures, machinery spaces, and other high-risk environments.

Using carbon dioxide (CO₂) as the extinguishing agent, these systems suppress fires by displacing oxygen around the ignition source — rapidly stopping combustion without leaving residue.

CO₂ is a proven clean agent for non-occupied enclosures, offering unmatched efficiency where traditional methods are not suitable.

How It Works

- Fire Detection

DHP systems detect heat through a pressurized polymer tube installed around risk areas.

IHP systems can detect through the same tube or via connected heat, smoke, or gas sensors.

- Activation

When exposed to high heat, the detection line bursts, or the control panel activates the solenoid valve.

- Agent Discharge

CO₂ is released instantly through discharge hoses and nozzles (IHP) or directly from the detection tube (DHP).

- Suppression

Oxygen is displaced, cutting off the fire’s ability to sustain combustion.

- Reset

- Cylinders are easily refilled, and detection tubing is replaced for continued protection.

System Overview

The Orbis® DHP (Direct High Pressure) and IHP (Indirect High Pressure) systems use high-pressure CO₂ cylinders that discharge the agent either:

Directly, through a heat-sensitive detection tube that ruptures at the fire’s origin (DHP mode).

Indirectly, through nozzles and discharge hoses, activated via heat detection tubing, electronic control panel, or manual release (IHP mode).

Both configurations deliver rapid, targeted suppression while maintaining simplicity, reliability, and minimal installation requirements.

Key Features

- Fast-acting suppression within seconds of detection

- Automatic or manual activation (heat tube, solenoid, or control panel)

- Residue-free agent – safe for sensitive electrical equipment

- No power requirement for direct systems

- Compact and modular for easy installation and maintenance

- Stainless steel cylinders and brass valves for corrosion resistance

- DOT, UL, TPED, and CE-certified components