CO₂ Fire Suppression Agent

Properties, Applications, Limitations & Safety Considerations

Carbon dioxide (CO₂) is one of the oldest and most widely used gaseous fire suppression agents for industrial, mechanical, and non-occupied hazard areas. It extinguishes fire by reducing oxygen concentration and cooling the combustion zone.FK-5-1-12 is the world’s leading environmentally friendly clean agent, providing fast fire suppression, zero equipment damage, and uninterrupted operational continuity.

What Is CO₂ Fire Suppression?

CO₂ fire suppression uses pressurized liquid carbon dioxide stored in cylinders.

Upon activation, the liquid expands into a gas or snow (depending on system design) and floods the hazard area.

• CO₂ is classified as:

• A clean, gaseous agent (no residue)

• Non-corrosive

• Non-conductive on energized electrical equipment

• Effective on Class B and C fires and many Class A surface fires

It is referenced in standards including NFPA 12 and ISO 6183.

How CO₂ Extinguishes Fires

CO₂ suppresses fires through two primary mechanisms:

1. Oxygen displacement (primary mechanism)

The agent reduces oxygen concentration in the hazard area to a level where combustion can no longer be sustained.

2. Cooling effect

Liquid CO₂ expands rapidly, absorbing heat as it vaporizes, which lowers the flame temperature.

Because CO₂ works by oxygen reduction, it is not recommended for occupied spaces at design concentrations.

Where CO₂ Is Typically Used

CO₂ is commonly selected for industrial hazards where high temperatures, deep-seated fires, and mechanical equipment are present.

Common applications include:

• Generator and turbine enclosures

• Industrial machinery spaces

• Power transmission equipment

• Printing presses

• Mechanical conveyor systems

• Transformers

• Paint booths and flammable liquid processes

• Engine compartments (marine or industrial)

• Unmanned electrical rooms

• High-risk fuel or hydraulic systems

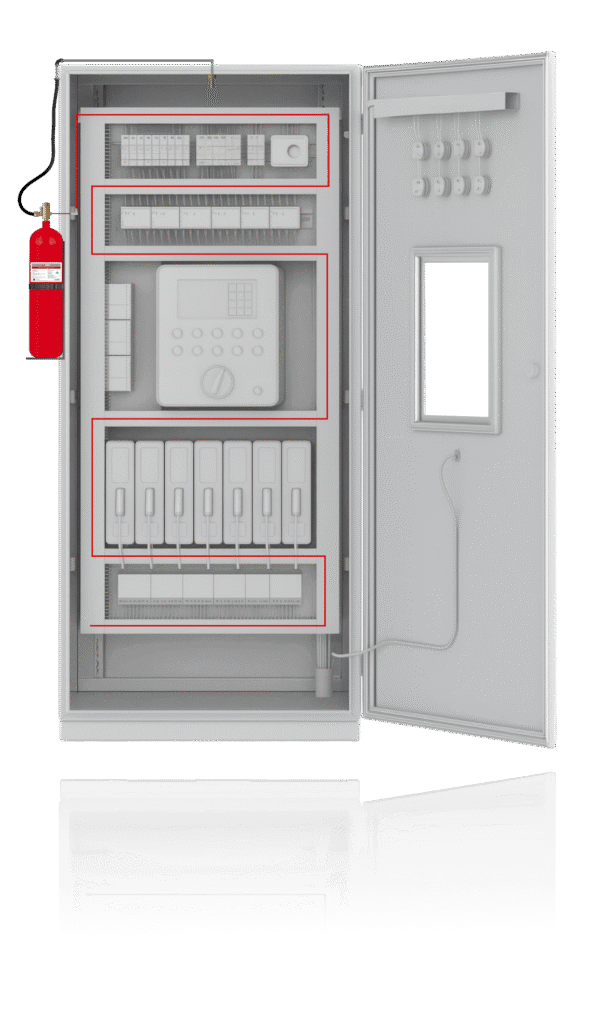

The agent is also used in micro-enclosure suppression, including high-pressure cylinder discharge into industrial cabinets.

Advantages of CO₂

• No residue after discharge; equipment can typically return to operation after ventilation.

• Effective on multiple fire classes, especially Class B and C.

• Non-conductive, allowing discharge onto energized electrical equipment.

• Suitable for harsh industrial environments where other clean agents may not perform well.

• Long history of documented use, testing, and performance data.

• Relatively low agent cost compared to halocarbons.

Limitations and Safety Concerns

CO₂ is effective but carries significant limitations and safety requirements that must be acknowledged.

1. Not safe for occupied spaces

CO₂ reduces oxygen to dangerously low levels.

Human exposure to design concentrations can cause:

• headaches

• impaired awareness

• unconsciousness

• respiratory arrest

Systems must incorporate:

• Pre-discharge alarms

• Time delays

• Evacuation protocols

• Lockout procedures

2. Requires sealed or semi-sealed environments

Total flooding systems need sufficient enclosure integrity to hold agent concentration.

3. High-pressure equipment

CO₂ cylinders are typically charged at 850 psi at 70°F (58 bar).

This requires:

• rated cylinders

• high-pressure fittings

• appropriate safety handling

4. Post-discharge ventilation is required

CO₂ must be evacuated before personnel re-enter.

5. Environmental considerations

While CO₂ has GWP = 1 (the reference baseline) and no chemical pollutants, its use still involves releasing pressurized CO₂, which has a carbon footprint.

Regulations vary by region regarding emissions, testing, and recharge requirements.

Is CO₂ Still a Good Choice?

CO₂ remains widely used in industrial settings due to its effectiveness and low cost.

However, it is not suitable for all applications, particularly:

• occupied rooms

• sealed IT spaces

• sensitive electronics where oxygen displacement poses a risk

Decision-making should consider:

• hazard type

• presence of personnel

• environmental footprint

• regulatory compliance

• alternative agents