How Orbis Fire Suppression Systems Work

Automatic, enclosure-level fire detection and suppression, engineered to stop fires at the source.

Why Pre-Engineered Systems Matter

Orbis Fire systems are pre-engineered to eliminate unnecessary complexity:

- No flow calculations required

- Faster installation and commissioning

- Predictable, repeatable performance

- Reduced engineering and labor cost

- Simplified maintenance and servicing

The Core Principle: Suppress Fires Where They Start

Electrical faults, thermal runaway, and component failures generate intense heat long before a fire becomes visible outside an enclosure. Traditional room-level detection or manual extinguishers often respond too late.

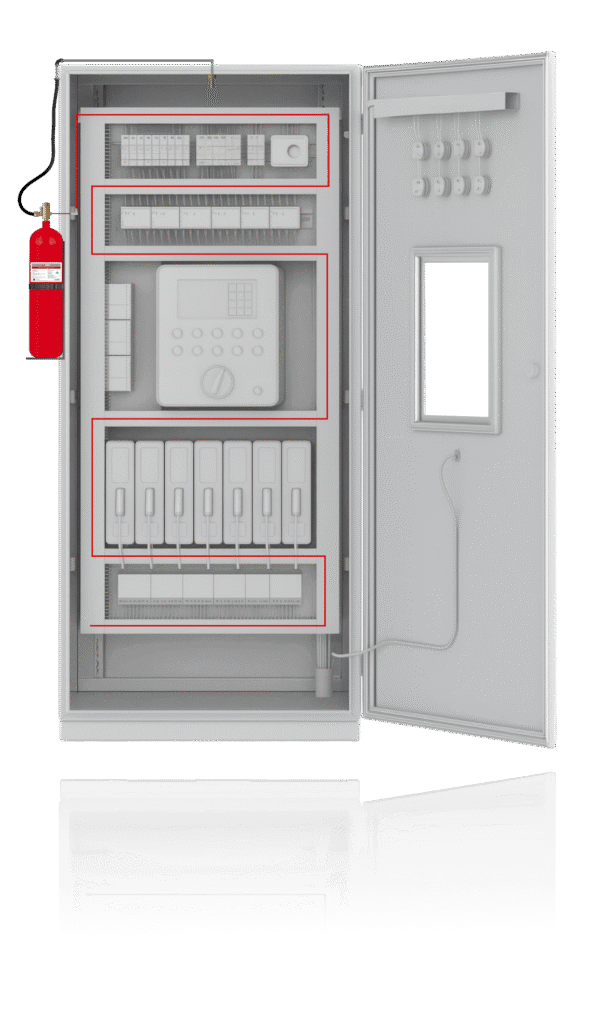

Orbis Fire systems are installed directly inside the protected enclosure, allowing fires to be detected and suppressed at their earliest stage—before escalation, spread, or secondary damage occurs.

The Orbis Fire Suppression Workflow

Step 1: Fire Detection

Fire conditions are identified directly inside the enclosure using one or more detection methods:

Heat-sensitive detection tubing routed near fire-prone components

Smoke detection for early particulate recognition

Gas detection where off-gassing or flammable buildup is a risk

Manual activation for operator-controlled discharge when required

Detection occurs at the source without relying on room sensors or external systems.

Step 2: System Activation

Once a fire condition is detected, the system activates automatically through one of the following mechanisms:

Mechanical or pneumatic activation triggered by pressure loss in detection tubing

Electrical activation via a solenoid connected to a control panel or detector

Manual actuation through a dedicated release device

Activation logic is selected based on enclosure size, risk profile, and operational requirements.

Step 3: Agent Discharge

After activation, the suppression agent is released into the enclosure using one of two discharge strategies:

Localized discharge for immediate suppression at the ignition point

Distributed nozzle discharge for broader or multi-zone enclosures

Agent release is rapid, controlled, and engineered to achieve effective concentration within the protected volume.

Step 4: Fire Suppression

The extinguishing agent suppresses the fire by rapidly removing heat, displacing oxygen, or interrupting the combustion process—depending on agent selection.

Because suppression occurs inside the enclosure, damage is minimized, downtime is reduced, and adjacent equipment remains unaffected.

Two Suppression Architectures

Orbis Fire systems are available in two fundamental protection architectures, selected based on enclosure size, complexity, and detection requirements.

Direct Low Pressure Clean Agent Release System (DLP)

Orbis Fire’s DLP fire suppression systems activate in seconds, using a heat-sensitive tube to release clean agent directly at the ignition point. Stainless steel, DOT & CE approved for global safety.

Indirect Low Pressure Clean Agent Release System (ILP)

Orbis Fire’s ILP fire suppression systems separate detection from discharge, using sensors or control panels to trigger clean agent release through nozzles. Stainless steel, DOT & CE approved for reliable protection worldwide.